There's a lot more to that question than you realize, but I'll take a (conservative) shot.

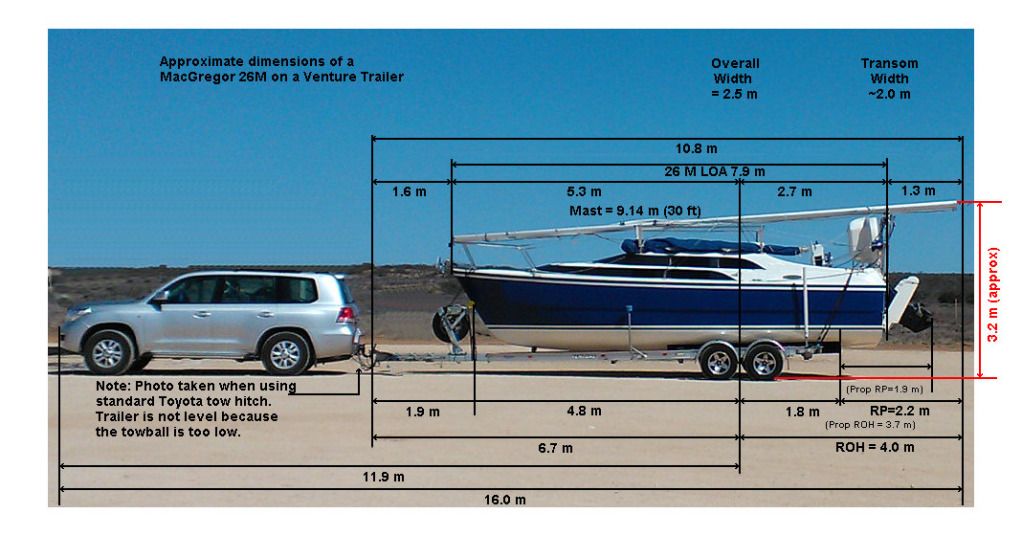

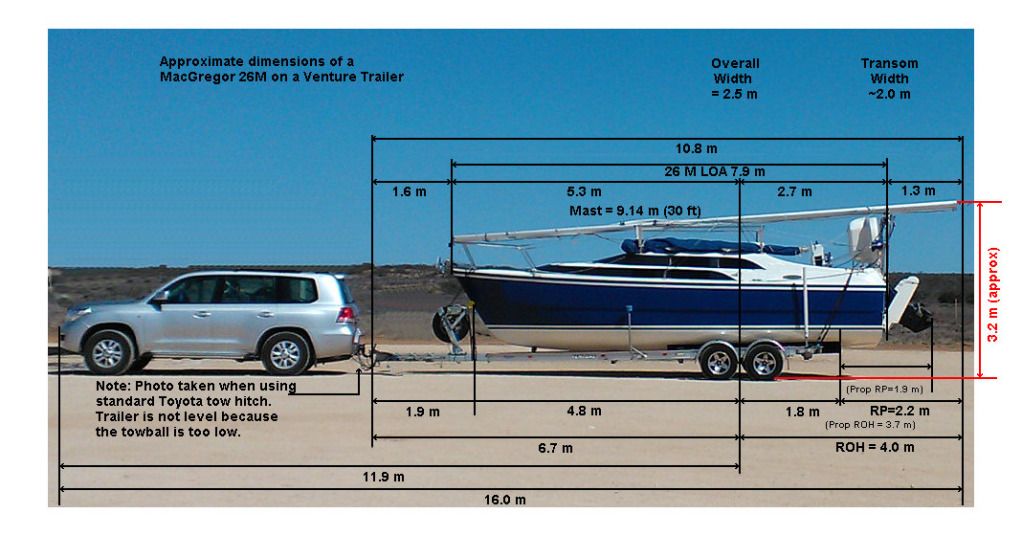

Here's the boat on its trailer (photo copied from a post on this forum).

The center of mass of the boat is just a little bit forward of the vertical line between the trailer axles. It probably weighs a little more than 3000 lb [1360 kg] with engine and 'stuff' inside.

The force on the two support points, one aft, and the other forward, depends on where the blocking is. If you block the stern about 2 meters back from that line, close to the OB, and block the bow twice that far forward of the line, then the stern blocking will take 2/3 of the vertical load, and the bow blocking will take 1/3. So the stern blocking will take

about 2000 lb [900 kg], and the bow blocking or cross member will hold

about 1000 lb [450 kg]. Since I (and you) don't know exactly how much your boat weighs, and where the CG is, it would be prudent to round up and even add some fudge if you think it's loaded a bit heavy.

This is where it gets a little dicey. For the cross member in the front, you need a wood or steel member that can resist the bending force of 1000 lb [450 kg] applied at the center of the span of 3m, . The ability of a member to support that load depends on the dimensions of the member, and the properties of the material it's made of.

I don't design in wood, so I'll stick with metal. The bending moment (a measure of how much bending 'force' the member has to resist) for a beam loaded at a point in the middle is simply one-half of the point load of 450 kg multiplied by the distance from the point load (the middle of the beam) to the support point at either end, which I'm assuming is one-half the length of the beam, or 59 inches [1.5 meters]. So the bending moment is 500 lb * 59 in = 29,500 lb-in (sorry, but gotta drop the metric here, as material properties in metric is not something I work with).

To resist that bending moment, the easiest way is to use a property of a member (a beam, in this case) called the section modulus, usually denoted as "S" in tables, which is published for common beams, tubes, and pipes. Assuming plain-vanilla steel with a yield stress of 36,000 lb/square inch, and applying a factor of safety of 2 (minimum, since there's a LOT of things about this that I don't know first-hand and for sure), you size the member to the bending moment divided by the material yield strength, which is 0.82 in^3. Applying a FoS of 2 gives you a required minimum section modulus of 1.7 in^3. Use a larger FoS if you think people will be on the boat, or if it may be heavier, or if you're uncomfortable in any way.

You can look up the properties of common structural members in various tables (including online). For schedule 40 pipe (don't know what you have available, though), a 3" pipe has a section modulus of 1.72 in^3, so would be adequate. But pipe, though readily available, is not a very efficient shape for this sort of loading. A square, or even better, rectangular tube, has more material where it's needed for this sort of loading. A 3 in x 3 in x 3/16 in wall square tube (hollow structural section, or HSS), which is what the pole tongue of the standard trailer for the X is made of, is just a shade light at 1.64 in^3, but it's close, though if you include it's own weight, it's not as close.

If at all uncomfortable with this, there is nothing wrong with upsizing a member. Weight of the member is not a consideration here for what you're doing (it's not an airplane, or a crane boom) other than to know that it has weight, which adds to the bending, so fudge on the safe side.

http://www.engineersedge.com/fluid_flow ... ule-40.htm

http://www.engineeringtoolbox.com/squar ... _1478.html

Keep in mind that I'm doing this sitting in front of a computer, without even a pencil and paper, and eyeball-estimating the location of the C of G or your boat, but I'll look closer at this if you want during the week.

And as always, don't get under a lifted load without proper support. Stick some blocking or a floor jack under the cross member when you don't need it clear. And if it were me, I'd bounce the load up and down to see if I could bend the support (with blocking under it with some clearance), just to be sure it's not marginal, before getting under it.