I just ran across this thread… where have I been!

I love it. Unfortunately, timing is everything in business. Before the housing debacle and my purchase of an ’08 26M, I would have gladly bought this boat.

Economies of scale make a huge difference in production costs. My base Mac was $20K. If I could get this boat with the equivalent exterior pieces (boat, trailer, rigging, main, no-engine, etc) and absolutely NO interior, I’d be happy as a clam. I’d fiberglass and wood up the interior, add the go-faster pieces at my leisure… in the ten year plan. Could a stripped down version (without interior) be created for even twice the price… $40K? Again… Roger’s mass production is hard (Hunter would say impossible) to compete with.

Unfortunately, IT IS after the housing debacle and I have a ’08 26M, I probably couldn’t get half of what I have into it. So I’m on the sidelines looking in…

… so I’ll arm-chair quarter back.

1) Have you considered using a resin infusion process. I’ve been designing a 40’ catamaran, using stitched instead of roving and epoxy instead of polyester. The result is a single hull goes from 1300 lbs to 670 lbs with an increase in strength, water permeability and several other benefits. It may guarantee keeping the boat light for both the performance reasons and not having to bump people up from mid-level SUVs to heavy duty pick-up trucks.

2) Considering how short and stubby a 26M is, it is remarkably cosmetic. Maybe I’m just a little partial. But you need to make sure you nail the topside, or you’ll just have another cargo container. Seems like someone (who has an eye for lines) needs to define the topsides, so you’ll know what you can do below.

3) I understand very well why you can’t change anything your tooling defines… width is fixed! Way too many things can get screwed up by trying to add even 6 inches. and the ONLY reason you might be able to get it even near our price range is the fact that all the fluid, strength, and stability analyses and all the tooling is ready to go…

4) Have you considered taking advantage of the extra height you’ll be adding in the cabin to allow the keel to be that much taller (and thus deeper)? Sounds like you could add two more feet of keel for that much more righting moment and… performance, stability and forgiveness.

5) Have you considered a semi wing type keel?... not so much for the fluid dynamics as the flatter, tucked up against the hull form factor. You might be able to lower the entire boat down on the trailer by nearly a foot with the resulting easing of launching per Roger’s 1” equals 1’ down the ramp theory.

6) Interior… I really like the curved designs. Have you considered the keel has to come up through there all the way to the roof, so the table and seating have to be cut to allow the movement?

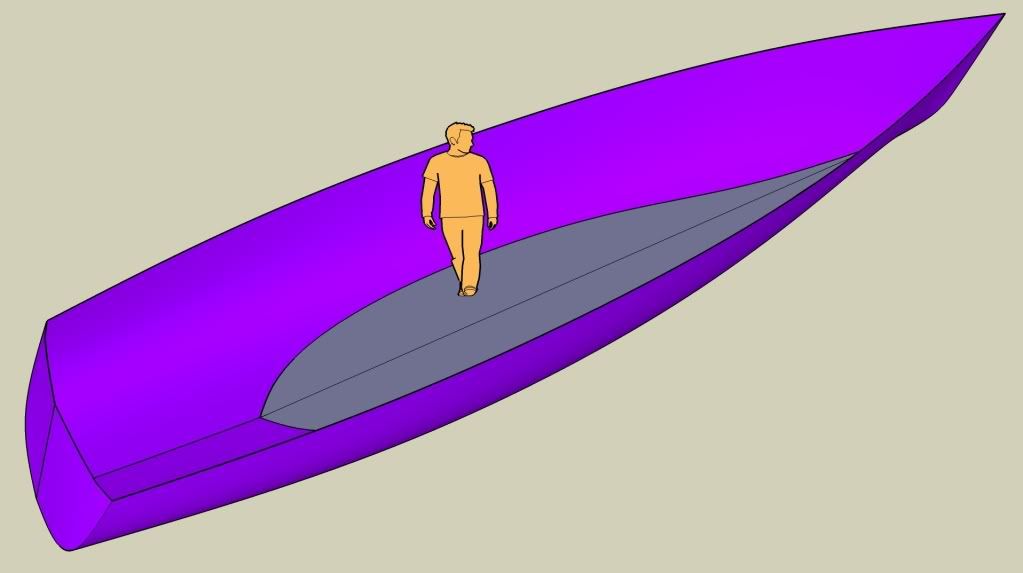

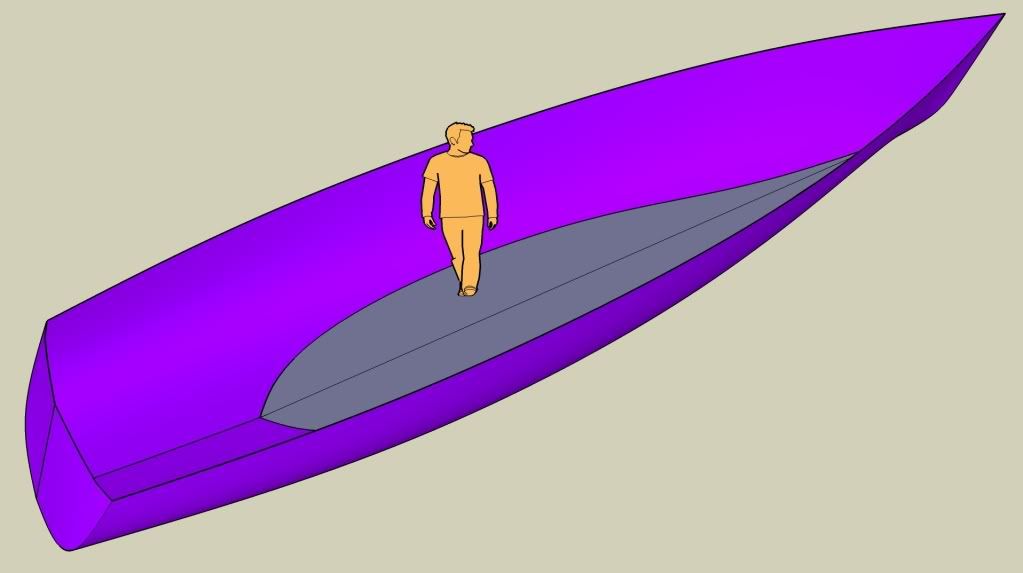

7) I started a 3D drawing, but the accuracy available from the line drawings on the Internet are not good enough to get the hull contours right which is important to determine interior volumes.

Maybe, my 401 will recover and I can still get one.