Mercury BigFoot 50 Overheating (long)

- Graham Carr

- First Officer

- Posts: 258

- Joined: Tue Feb 10, 2004 9:19 pm

- Sailboat: MacGregor 26X

- Location: Sedro-Woolley WA, 2002 26X , Mercury 50hp 4 Stroke Bigfoot "Pauka2"

Dimitri I just got back from vacation so I only just read the latest post. Sorry I did not pay attention that you had a 2001 engine. My service manual is for 2002 & newer.

I would be careful before closing down the pee flow until you know for a fact the flow does not cool important components. To recap what I said early. At the base of the block the water splits. The bulk flows to the head but a part of the flow is directed into the base of the water jacket cover. The water exits the base of the jacket via tubing and is routed through the fuel cooler and fuel pump, then exits the tell-tale (pee hole). In this case if the p-hole was blocked, cooling water for the fuel system would stop.

Graham

I would be careful before closing down the pee flow until you know for a fact the flow does not cool important components. To recap what I said early. At the base of the block the water splits. The bulk flows to the head but a part of the flow is directed into the base of the water jacket cover. The water exits the base of the jacket via tubing and is routed through the fuel cooler and fuel pump, then exits the tell-tale (pee hole). In this case if the p-hole was blocked, cooling water for the fuel system would stop.

Graham

- Dimitri-2000X-Tampa

- Admiral

- Posts: 2043

- Joined: Fri Jan 02, 2004 5:36 am

- Sailboat: MacGregor 26X

- Location: Tampa, Florida 2000 Mercury BigFoot 50HP 4-Stroke on 26X hull# 3575.B000

Here's an update to my ongoing saga...

I wasn't able to properly ream the tube from below. Even cut off a piece of my metal fish tape but that still couldn't get it up the length of the tube.

I pulled the lower unit .. again .. and put the flusher muffs on to see if there were water leaks around the water pump. Sure enough, there was some water leaking under the gaskets which means it could be sucking air. Also, I had never put a silicone "dam" type seal between water pump compartment and exhaust area. So, I rebuilt my water pump for the third time and this time replaced the water pump base which was badly pitted and wasn't sealing well. I also put some high temp RTV silicone in the right area and put it back together. I am now only testing it in a trash can and not using flusher muffs. Pee stream is now slightly stronger, but not strong enough so problem still persists.

At this point, the only option left is pulling the powerhead. I'm going to do it myself I decided...after this much effort. I will rig 3 4x4's and a comealong as a hoist. I'm just waiting for the overpriced parts to come from Mercury. If you follow my thread in the iboats forum, you will see that I have found one other case of exactly what I am going through. Interestingly enough, the motor is also on a Mac 26X just about a 100 miles south of here, but happened 2 years ago. Its quite the coincidence since virtually all iboats users are powerboaters so to find someone with a 26X with the exact same model and year of my bigfoot was quite a coincidence. I don't suppose the guy hangs out around here? His handle on Iboats was "Picco" but he didn't post again after he solved his problem by pulling the powerhead. Most people probably have the dealer do this so I never hear about the details on the forums.

To sum it up, I think this engine must have a cooling system design flaw for saltwater usage. What I am expecting to find is that galvanic corrosion from where the copper water tube touches the aluminum block has swelled up the rubber grommet effectively cutting down water flow to enough of a degree to cause not enough pressure and volume in the power head. From researching the iboats forum, seems like there are a lot of other motor types that suffer from this problem too.

Graham, my motor is a 2000 model year, they underwent some sort of design change in 2001 when EFI was added. The diagram that Midget mailed me is for the newer model motor but it turns out that most of it looks very similar to mine. The only difference I can see is that the telltale hose flow also cools a couple of fuel related components (ie, fuel pump) whereas on mine, it just shoots straight overboard from the water jacket. The diagram does not have enough detail to show the split off at the base of the powerhead although I think it does actually split there somehow since there has to be some sort of bypass when the thermostat is closed. Also, there is no detail to show how the exhaust bypass works (hole below telltale hole). Looks like only way to find this out is by reverse engineering when I pull the sucker apart.

Oh well, so much for the nice spring boating season in Florida...missed it this year. I obviously move very slowly through this with my other time commitments and in hindsight, I wish I had taken it into the shop some months ago...but at least I gained an education here which could come in handy if I ever do any serious cruising on this boat. Hopefully, the final conclusion to this story will be posted in a week or two.

I wasn't able to properly ream the tube from below. Even cut off a piece of my metal fish tape but that still couldn't get it up the length of the tube.

I pulled the lower unit .. again .. and put the flusher muffs on to see if there were water leaks around the water pump. Sure enough, there was some water leaking under the gaskets which means it could be sucking air. Also, I had never put a silicone "dam" type seal between water pump compartment and exhaust area. So, I rebuilt my water pump for the third time and this time replaced the water pump base which was badly pitted and wasn't sealing well. I also put some high temp RTV silicone in the right area and put it back together. I am now only testing it in a trash can and not using flusher muffs. Pee stream is now slightly stronger, but not strong enough so problem still persists.

At this point, the only option left is pulling the powerhead. I'm going to do it myself I decided...after this much effort. I will rig 3 4x4's and a comealong as a hoist. I'm just waiting for the overpriced parts to come from Mercury. If you follow my thread in the iboats forum, you will see that I have found one other case of exactly what I am going through. Interestingly enough, the motor is also on a Mac 26X just about a 100 miles south of here, but happened 2 years ago. Its quite the coincidence since virtually all iboats users are powerboaters so to find someone with a 26X with the exact same model and year of my bigfoot was quite a coincidence. I don't suppose the guy hangs out around here? His handle on Iboats was "Picco" but he didn't post again after he solved his problem by pulling the powerhead. Most people probably have the dealer do this so I never hear about the details on the forums.

To sum it up, I think this engine must have a cooling system design flaw for saltwater usage. What I am expecting to find is that galvanic corrosion from where the copper water tube touches the aluminum block has swelled up the rubber grommet effectively cutting down water flow to enough of a degree to cause not enough pressure and volume in the power head. From researching the iboats forum, seems like there are a lot of other motor types that suffer from this problem too.

Graham, my motor is a 2000 model year, they underwent some sort of design change in 2001 when EFI was added. The diagram that Midget mailed me is for the newer model motor but it turns out that most of it looks very similar to mine. The only difference I can see is that the telltale hose flow also cools a couple of fuel related components (ie, fuel pump) whereas on mine, it just shoots straight overboard from the water jacket. The diagram does not have enough detail to show the split off at the base of the powerhead although I think it does actually split there somehow since there has to be some sort of bypass when the thermostat is closed. Also, there is no detail to show how the exhaust bypass works (hole below telltale hole). Looks like only way to find this out is by reverse engineering when I pull the sucker apart.

Oh well, so much for the nice spring boating season in Florida...missed it this year. I obviously move very slowly through this with my other time commitments and in hindsight, I wish I had taken it into the shop some months ago...but at least I gained an education here which could come in handy if I ever do any serious cruising on this boat. Hopefully, the final conclusion to this story will be posted in a week or two.

- Dimitri-2000X-Tampa

- Admiral

- Posts: 2043

- Joined: Fri Jan 02, 2004 5:36 am

- Sailboat: MacGregor 26X

- Location: Tampa, Florida 2000 Mercury BigFoot 50HP 4-Stroke on 26X hull# 3575.B000

Here is the conclusion to the 7 month saga. The good thing about deciding to do it myself is that I took some pictures. From what I read on Iboats, I'm not the first person to have this exact same problem with a bigfoot motor used in saltwater. Seems like there are a lot of Macs with BF's on them so something to look forward to if you use your boat in salt a lot. Before I ran into this problem, I probably used my boat 2-4 times a month so perhaps if it is used less often, the problem will take longer to manifest. Also, maybe the way I flush could have had adverse affects.

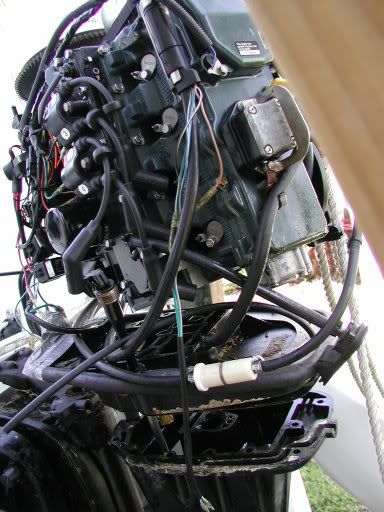

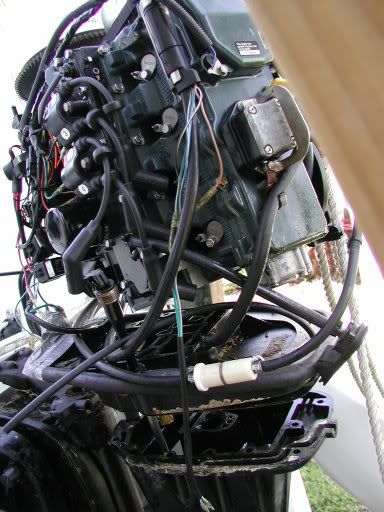

Here is a pic of the frame made from scrap lumber and a come-along I jerry rigged to lift the powerhead.

I didn't follow all the shop manual instructions to the letter. There is no need to remove all the throttle/transmission/electrical cables etc. unless you plan to take the powerhead completely away (like to a machine shop for example). The instructions also say to drop the lower unit and drain the oil first. I didn't do either of those steps because I had just nicely sealed my lower unit after the 3rd pump rebuild and also, my expensive Mercury 4-stroke oil only had a couple hours of use on it so I figured I would only drain it if I contaminated it real bad. To keep the transmission shifter rod in the right place, I put duct tape on it after I lifted the powerhead. This kept it aligned perfectly so it would drop back down into the same position during re-assembly. In hindsight, the job would have been a bit easier if I had pulled the lower unit though. It took me a couple hours to get the upper mount bolts off because of the fact that the driveshaft was still coming through the adapter plate. I could have dropped and replaced the lower unit in about half that time or less but once I was committed, I couldn't tilt the motor back up unless I decided to drain the oil.

Here is a pic of how I left the powerhead, adapter plate, and mid unit somewhat attached while I did the job. Just dissasembled enough to get to the culprit area.

On this next pic, I should have taken the picture more from the top so you could see how constricted the water passageway had gotten to the engine. You can certainly see how bad it looks compared to the new one in the next picture though. I would estimate that the passageway was about half the diameter that it should have been. Not sure about all the math, but I feel pretty confident that this would have cut out at least half the correct water flow, maybe even closer to 2/3. This of course explains why the problem only occured under heavier load (except during a brief time that I must have picked up some extra sand which blocked the hole even more).

And finally, the picture of how it looked after I fixed it. What happened is that salt buildup, other minerals, and corrosion (mostly salt build up) got all around the grommet and effectively "squeezed" it down to a much smaller hole. Also, the rubber of the grommet had lost most of its strength and was deteriorating badly. I suppose this may have something to do with the dissimilar metals in close proximity (copper and aluminum). Getting the old grommet out was also a difficult part of the job. It had to come out in little pieces and I had to be very careful not to contaminate the oil. Probably took 2+ hours just to do this and then scrape out the grommet hole enough so that the new grommet would go all the way in.

So, why did this happen? I suspect it is mostly due to saltwater use plus the fact that I probably use my engine more than most Mac owners. I wouldn't go as far as to think that freshwater use keeps you completely safe as there are minerals in freshwater too but its likely it would take a lot longer to go bad. The design is also in question as the BF has a huge waterpump, same as used in 200-300HP models. The size of the tube is first stepped down between water pump and copper tube but then is further stepped down at the powerhead. I expect the powerhead was designed for a much smaller pump and so there really is a lot of water pressure into the relatively small block due to the step downs. But I did do some introspection to my flushing habits also.

The PO told me that the dealer advised him to only turn the hose on half way during flushing or it could blow the hose. I think this is bogus as I have now tested it with up to 70PSI house pressure and it did not blow the hose. I will use full pressure from now on. Also, ever since I had a cracked aluminum head on a car motor when I was a teenager, I'm afraid of shooting cold water into a hot head so sometimes I would wait until the next day to flush because it would get dark. Once in a while, the motor wouldn't get flushed until the next use a week or two later. I won't be doing that anymore either although I still don't think its a good idea to flush a very hot motor so I try to let it cool down at least a half an hour first. I realize that this means the thermostat has closed down and fresh water may not get through every passageway, but this is better than a cracked block or head. It also gets clean water down through that nasty grommet.

I also replaced the telltale fitting (pee hole) as the PO had reamed the hole out to the same size as the hose. This was another overpriced part (28 bucks) but the new one has a much smaller exit hole. This is quite important as the larger hole drops the pressure in the head too much. Now the motor can run at WOT all day long again and the pee stream is so strong where it hits the water behind the motor, that it creates foam in the water. Over time, its easy to forget how strong this stream should really be!

Here is a pic of the frame made from scrap lumber and a come-along I jerry rigged to lift the powerhead.

I didn't follow all the shop manual instructions to the letter. There is no need to remove all the throttle/transmission/electrical cables etc. unless you plan to take the powerhead completely away (like to a machine shop for example). The instructions also say to drop the lower unit and drain the oil first. I didn't do either of those steps because I had just nicely sealed my lower unit after the 3rd pump rebuild and also, my expensive Mercury 4-stroke oil only had a couple hours of use on it so I figured I would only drain it if I contaminated it real bad. To keep the transmission shifter rod in the right place, I put duct tape on it after I lifted the powerhead. This kept it aligned perfectly so it would drop back down into the same position during re-assembly. In hindsight, the job would have been a bit easier if I had pulled the lower unit though. It took me a couple hours to get the upper mount bolts off because of the fact that the driveshaft was still coming through the adapter plate. I could have dropped and replaced the lower unit in about half that time or less but once I was committed, I couldn't tilt the motor back up unless I decided to drain the oil.

Here is a pic of how I left the powerhead, adapter plate, and mid unit somewhat attached while I did the job. Just dissasembled enough to get to the culprit area.

On this next pic, I should have taken the picture more from the top so you could see how constricted the water passageway had gotten to the engine. You can certainly see how bad it looks compared to the new one in the next picture though. I would estimate that the passageway was about half the diameter that it should have been. Not sure about all the math, but I feel pretty confident that this would have cut out at least half the correct water flow, maybe even closer to 2/3. This of course explains why the problem only occured under heavier load (except during a brief time that I must have picked up some extra sand which blocked the hole even more).

And finally, the picture of how it looked after I fixed it. What happened is that salt buildup, other minerals, and corrosion (mostly salt build up) got all around the grommet and effectively "squeezed" it down to a much smaller hole. Also, the rubber of the grommet had lost most of its strength and was deteriorating badly. I suppose this may have something to do with the dissimilar metals in close proximity (copper and aluminum). Getting the old grommet out was also a difficult part of the job. It had to come out in little pieces and I had to be very careful not to contaminate the oil. Probably took 2+ hours just to do this and then scrape out the grommet hole enough so that the new grommet would go all the way in.

So, why did this happen? I suspect it is mostly due to saltwater use plus the fact that I probably use my engine more than most Mac owners. I wouldn't go as far as to think that freshwater use keeps you completely safe as there are minerals in freshwater too but its likely it would take a lot longer to go bad. The design is also in question as the BF has a huge waterpump, same as used in 200-300HP models. The size of the tube is first stepped down between water pump and copper tube but then is further stepped down at the powerhead. I expect the powerhead was designed for a much smaller pump and so there really is a lot of water pressure into the relatively small block due to the step downs. But I did do some introspection to my flushing habits also.

The PO told me that the dealer advised him to only turn the hose on half way during flushing or it could blow the hose. I think this is bogus as I have now tested it with up to 70PSI house pressure and it did not blow the hose. I will use full pressure from now on. Also, ever since I had a cracked aluminum head on a car motor when I was a teenager, I'm afraid of shooting cold water into a hot head so sometimes I would wait until the next day to flush because it would get dark. Once in a while, the motor wouldn't get flushed until the next use a week or two later. I won't be doing that anymore either although I still don't think its a good idea to flush a very hot motor so I try to let it cool down at least a half an hour first. I realize that this means the thermostat has closed down and fresh water may not get through every passageway, but this is better than a cracked block or head. It also gets clean water down through that nasty grommet.

I also replaced the telltale fitting (pee hole) as the PO had reamed the hole out to the same size as the hose. This was another overpriced part (28 bucks) but the new one has a much smaller exit hole. This is quite important as the larger hole drops the pressure in the head too much. Now the motor can run at WOT all day long again and the pee stream is so strong where it hits the water behind the motor, that it creates foam in the water. Over time, its easy to forget how strong this stream should really be!

- Night Sailor

- Admiral

- Posts: 1007

- Joined: Mon Dec 26, 2005 4:56 pm

- Sailboat: MacGregor 26X

- Location: '98, MACX1780I798, '97 Merc 50hp Classic, Denton Co. TX "Duet"

Thanks

Although my Merc is a classic 50 from 1997 and runs flawlessly, I'm always interested in the problem solving on Mercs. Thanks for the completeness and honesty of your break downs, trials and reports of the solutions. I'm sure you will be helping a lot of folks take better care of their engines, and be more knowledgeable about future issues when they take them into the shop for repairs.

-

Frank C

- Dimitri-2000X-Tampa

- Admiral

- Posts: 2043

- Joined: Fri Jan 02, 2004 5:36 am

- Sailboat: MacGregor 26X

- Location: Tampa, Florida 2000 Mercury BigFoot 50HP 4-Stroke on 26X hull# 3575.B000

Perhaps the classic 50 is not as vulnerable if the theory of the bigfoot having more water pressure than the powerhead was designed for holds water. Be interesting to see if any Yamaha High Thrust folks have had this trouble.

If I recall correctly, when you flush a Mercury, the water goes from the telltale hose straight into the second water jacket compartment. Both water jacket compartments surround the exhaust manifold but the water from the pump comes up the first compartment which is further from the combustion chamber, then back down through the second compartment, then into the head and cylinder area. When the motor is running, the outer part of the exhaust manifold kind of preheats the water somewhat. This is why the water out of the telltale is warmer than ambient water but not as hot as what comes out the exhaust hub (which has also gone through the oil pan by then too). For that matter, the exhaust area is right next to the water pump so I wouldn't be surprised if the water is starting to pick up some heat even before it even enters the block.

I suppose I'm being a bit overly paranoid but do you guys run a motor really hard, shut it down and flush immediately with cold tap water? Perhaps the motor is designed even for flush water to pick up some heat in the exhaust manifold area before hitting the cylinder head which would cool the really hot parts somewhat more gradually compared to water which had not snaked through the manifold/jacket compartments first.

If I recall correctly, when you flush a Mercury, the water goes from the telltale hose straight into the second water jacket compartment. Both water jacket compartments surround the exhaust manifold but the water from the pump comes up the first compartment which is further from the combustion chamber, then back down through the second compartment, then into the head and cylinder area. When the motor is running, the outer part of the exhaust manifold kind of preheats the water somewhat. This is why the water out of the telltale is warmer than ambient water but not as hot as what comes out the exhaust hub (which has also gone through the oil pan by then too). For that matter, the exhaust area is right next to the water pump so I wouldn't be surprised if the water is starting to pick up some heat even before it even enters the block.

I suppose I'm being a bit overly paranoid but do you guys run a motor really hard, shut it down and flush immediately with cold tap water? Perhaps the motor is designed even for flush water to pick up some heat in the exhaust manifold area before hitting the cylinder head which would cool the really hot parts somewhat more gradually compared to water which had not snaked through the manifold/jacket compartments first.

- Chip Hindes

- Admiral

- Posts: 2166

- Joined: Mon Jan 05, 2004 6:13 am

- Location: West Sand Lake, NY '01X, "Nextboat" 50HP Tohatsu

I believe you guys who won't run cold water through your motors should rethink. If you use "Mickey Mouse" flushing ears the water goes in and comes out the same way as if the motor were in the water, and most of these motors will run fine in any water which is in liquid form, including below 32F if it's salt water. They're designed to run with coolant water which is literally hundreds of degrees below engine temp. That's why they have thermostats. I believe it's pretty unlikely that the flushing water will be any colder than the water in which they're normally run.

IMO you're apt to be doing more damage to the motor by leaving it unflushed for hours, or as it appears in some cases, days or weeks, as you would by running cold water through it to flush it.

How hot is it when you shut it down, and how quickly after that shutdown can you flush it, anyway? It's good practice after a high speed run to let it cool down at low speed or idle for a few minutes anyway before shutting down, and it takes at least several minutes then to get it on the trailer and out of the water before you can even think about flushing it. If it still bothers you wait to flush until after it's derigged.

IMO you're apt to be doing more damage to the motor by leaving it unflushed for hours, or as it appears in some cases, days or weeks, as you would by running cold water through it to flush it.

How hot is it when you shut it down, and how quickly after that shutdown can you flush it, anyway? It's good practice after a high speed run to let it cool down at low speed or idle for a few minutes anyway before shutting down, and it takes at least several minutes then to get it on the trailer and out of the water before you can even think about flushing it. If it still bothers you wait to flush until after it's derigged.

- aya16

- Admiral

- Posts: 1362

- Joined: Fri Feb 18, 2005 6:29 am

- Location: LONG BEACH CALIF Mac M 04 WHITE

Glad you solved the problem. as far as flushing I wouldnt worry about it at all I agree with Chip. by the time you have your boat on the trailer and

hooked up to flush you can bet the engine has cooled alot. I use full pressure when flushing because the ears let a lot of water escape before it gets in the engine. And its really no diff. then running your engine then stopping then starting again so I wouldnt sweat it.

hooked up to flush you can bet the engine has cooled alot. I use full pressure when flushing because the ears let a lot of water escape before it gets in the engine. And its really no diff. then running your engine then stopping then starting again so I wouldnt sweat it.